Artificial Intelligence in Manufacturing

Go beyond industry 4.0 with total visibility, predictive insights, and prescriptive actions

SparkCognition accelerates digital transformation for the world’s leading manufacturers in process, discrete, and batch operations. Our proven solutions for AI in manufacturing provide predictive maintenance, process optimization, and prescriptive actions that enable you to increase throughput, reduce costs, and save energy.

Artificial Intelligence in Manufacturing

Go beyond industry 4.0 with total visibility, predictive insights, and prescriptive actions

SparkCognition accelerates digital transformation for the world’s leading manufacturers in process, discrete, and batch operations. Our proven solutions for AI in manufacturing provide predictive maintenance, process optimization, and prescriptive actions that enable you to increase throughput, reduce costs, and save energy.

Proven Value

“SparkCognition’s ability to deliver reliable, AI-based predictive analytics helps the people working with and on the equipment to not only know what is happening, but more importantly, what is going to happen, and when. This is a game changer. Not only does this improve plant safety, but it increases productivity by reducing unplanned downtime.”

Doug Smith, CEO, Texmark Chemicals, Inc.

Accelerate your digital transformation with AI in manufacturing

Manufacturing requires you to adapt effectively to evolving conditions in your plant. But much of the current factory tech stack is fragmented, dated, proprietary, siloed, or even all of the above. Legacy frontline systems are struggling to keep pace with widespread industry challenges like skilled labor shortages, regulatory compliance, supply-chain issues, and surging demand.

Here’s the good news: no matter where you are on your digital journey today, you will become an industry 4.0 leader faster with SparkCognition’s easily operationalized, scalable, and high ROI products for AI in manufacturing. SparkCognition Industrial AI Suite provides end-to-end visibility and captures real-time insights to enable predictive maintenance and prescriptive actions that optimize throughput and reduce unnecessary strain on your resources. Realize the transformative power of artificial intelligence in manufacturing—by harnessing the power of data you already have.

Ready to unlock unprecedented business insights from your data?

Relieve the painful cost of downtime using artificial intelligence in manufacturing

Downtime cost averages $532,000 per hour for large manufacturing companies, and human error causes 23% of unplanned downtime in manufacturing—more than twice the rate of other sectors.

With real-time insights and predictive alerts on your machine health, SparkCognition Industrial AI Suite for Manufacturing help you avert costly micro-stoppages, slowdowns, and unscheduled downtime events before they happen.

Watch our webinar: AI in Manufacturing—From Data Disorder to Operational Insights

Discover next-best-action recommendations with AI in manufacturing

By the end of the decade, the growing skill-shortage problem could put nearly $500B of manufacturing GDP at risk. With experienced workers leaving the workforce and hiring markets more competitive every day, it’s time to rethink the way people and technology work together. Prescriptive insights remove the guesswork by providing root cause analysis to prevent unnecessary repairs. SparkCognition allows you to codify SME manufacturing knowledge into one central source of truth, with next-best-action recommendations that become even more accurate and precise over time.

Learn more: How Prescriptive Insights Help Manufacturers Improve Throughput

Achieve sustainability goals through AI in manufacturing insights

Manufacturers account for more than 30% of the nation’s total energy consumption. Yet, only 1 in 10 are on track to achieve their sustainability goals.

SparkCognition’s AI in manufacturing solutions alert you to wasteful electricity, water, or other resource usages, allowing you to analyze past anomalies and alerts to find root causes and patterns in resource usage, correlate usage practices with production and/or quality issues, and extend your asset’s usable life while maximizing throughput through optimization actions.

Read our blog: How Normal Behavior Modeling Turns Data Into Insights for Industrials

Case studies: AI in manufacturing companies improving operational efficiency and sustainability

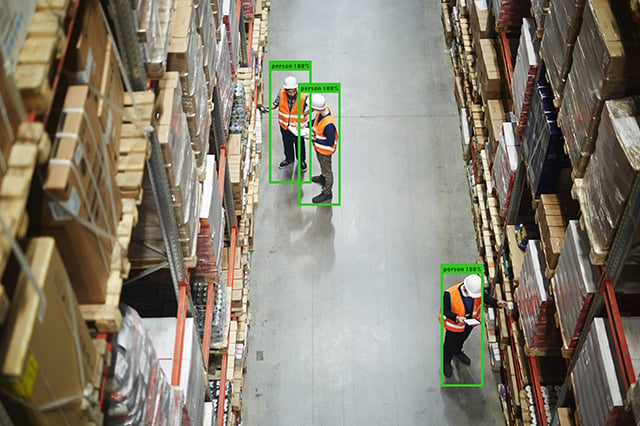

Use Case: Preventing Forklift Accidents with Visual AI Advisor

Optimize Workplace Safety with Visual AI Advisor

How to become an industry 4.0 leader using AI-enabled predictive maintenance

Driving sustainability for a Top 50 beverage manufacturer

Optimizing production via AI-powered transparency

Unlock the power of AI in manufacturing

Leveraging deep manufacturing industry knowledge, SparkCognition unlocks the power of AI in manufacturing at scale so you can leap ahead of your competitors held back by fragmented and dated legacy systems.

A fortune 50 beverage manufacturer saw production efficiency increase by up to 5%, averting nearly $1M in maintenance costs through a single plant deployment.